Titanium Vs Aluminum for Racking

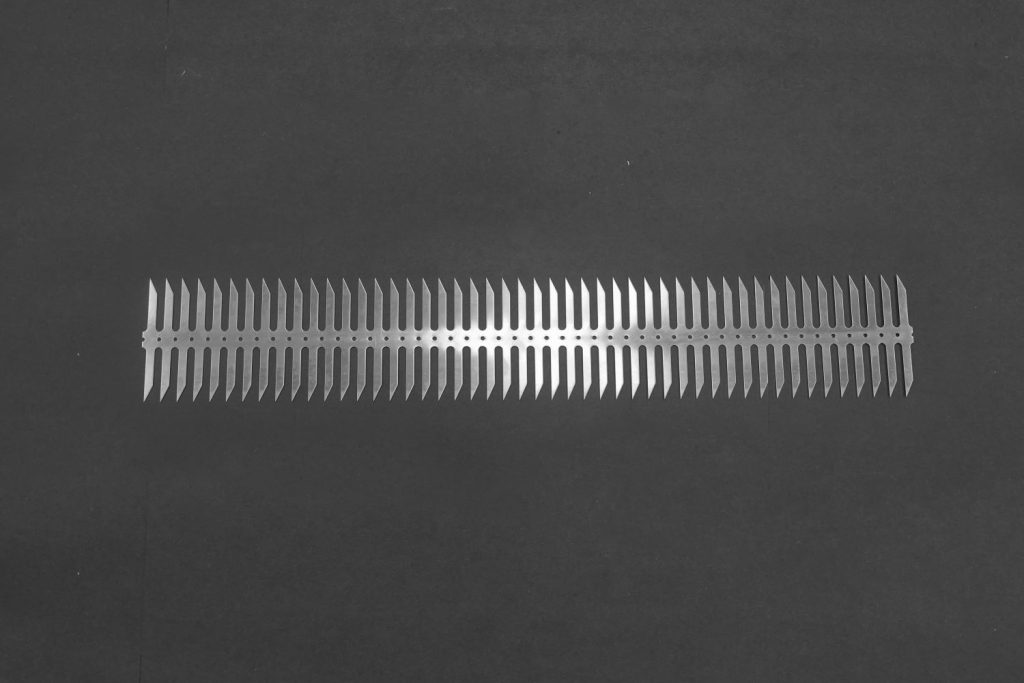

When it comes to anodizing, there are several material options for fixturing. Titanium, aluminum, and welding are some of the options. Titanium is used in baskets, clips, clamps, racks, and nuts and bolts as well as in combinations of aluminum and titanium. Aluminum is used in racks, clips, and wire when fixturing a part. The material chosen for racking your part has many implications on the outcome of the process including quality and energy used. Aluminum is far more conductive than titanium, resulting in better quality on the anodized part while also conserving energy both in electricity and cooling. While titanium isn’t consumed during processing like aluminum is, few companies fail to look beyond this fact when considering the total benefits of aluminum in terms of energy saved, vastly improved quality (especially when running 7000 and 2000 series alloys) and the cost of aluminum Vs. the cost of titanium.

Here’s a direct comparison of titanium vs. aluminum in terms of electrical conductivity and ampacity per square inch, using standard reference values for wrought, uncoated aluminum:

1. Electrical Conductivity

| Property | Titanium (Grade 2 or 5) | Aluminum (Wrought, e.g., 1350-H19 or 6061-T6) |

| Electrical Conductivity (% IACS) | ~1.2–3.1% IACS | ~35–62% IACS (6061: ~40%, 1350: ~61%) |

| Electrical Resistivity (µΩ·cm) | ~42–80 µΩ·cm | ~2.82–4 µΩ·cm |

IACS = International Annealed Copper Standard (100% IACS = 58 MS/m)

Bottom Line:

Aluminum is at least 10–50 times more conductive than titanium depending on grade.

2. Ampacity per Square Inch

This value depends on installation (air, conduit, insulation, etc.) and temperature rating. But typical ampacity estimates for bare wire in free air are:

| Material | Approximate Ampacity (A/in²) |

| Titanium | ~8–15 A/in² |

| Aluminum (1350) | ~600–700 A/in² |

| Aluminum (6061) | ~270–350 A/in² |

For aluminum, 1350 is a high-conductivity grade used for electrical applications. Most wires used in anodizing are 1000 series aluminum.

Bottom Line:

Aluminum carries vastly more current per square inch than titanium — by a factor of 20 to 70 times depending on the aluminum grade and titanium alloy.

Summary

| Metric | Titanium | Aluminum (Wrought, Bare) |

| Conductivity (% IACS) | 1.2–3.1% | 35–62% |

| Ampacity (A/in²) | 8–15 A/in² | 270–700 A/in² |

| Relative Efficiency | ≪ Much lower | ≫ Much higher |

The conductivity of aluminum as compared to titanium makes it the clear choice when quality is critical.

Notes: IACS stands for International Annealed Copper Standard, and it’s a way to measure and compare the electrical conductivity of different materials. It’s based on the conductivity of annealed copper, which is defined as 100% IACS at 20°C. The higher the %IACS value, the better the material conducts electricity.

Ampacity: Ampacity refers to the maximum amount of electric current (measured in amperes) that a wire or cable can safely carry continuously without overheating. Ampacity is the highest amperage a wire can handle without exceeding its temperature rating. It essentially describes the current-carrying capacity of a conductor under specific operating conditions.